This product is used in applications where two air streams are not in close proximity and either the distance exceeds those that the split passive product HRM-VTM can be applied or where two season recovery is required regardless of air stream location.

The SMART Water-Glycol Pump system takes advantage of our pedigree in making optimized heat pipe coils and brings that technology into water coils. By designing the whole system, HPT is able to provide a solution that out performs most glycol systems, with sensible effectiveness >50% for a 6 row system at 500 FPM. This is key when trying to meet ASHRAE Standard 90.1 Section 6.7.7.3 for Laboratory Exhaust Systems.

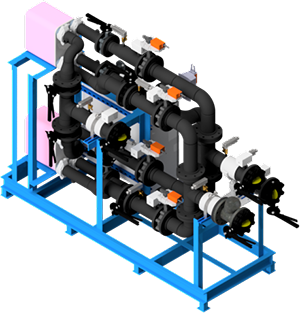

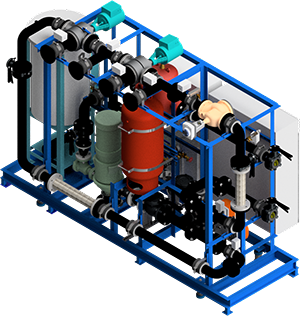

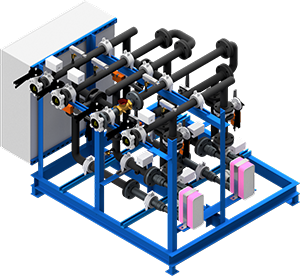

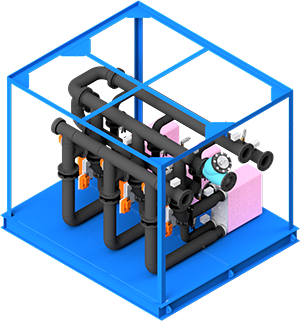

The system comprises a pump skid, coils and air sensors, which all ship from HPT. The contractor will pipe between coils and skid, wire the power supply, Building Management System (BMS) and air sensors, and provide standard hydronic services such as startup and installing insulation. The skid includes all the hydronic components, electrical components and water sensors, which are all fully installed in the factory and ready to use.

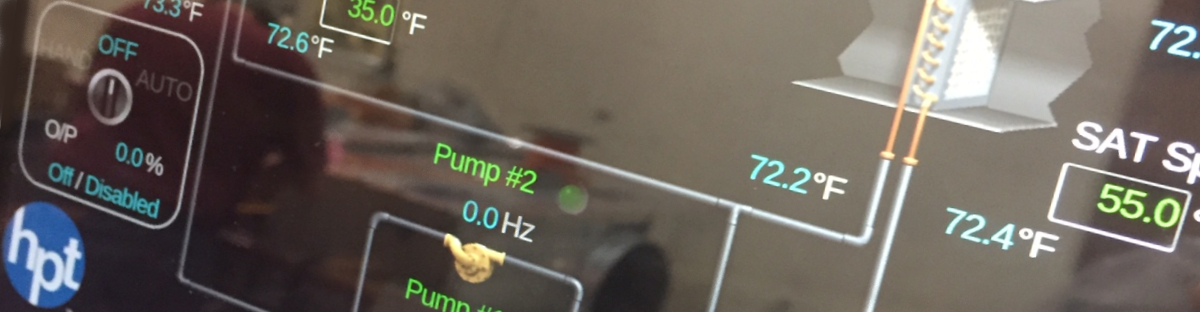

The system controller modulates valve positions and pump speeds to maintain optimal performance during different times of the year, including heating, cooling, economizer and frost control. The 10” touchscreen interface provides a tactile and intuitive representation of the system so maintenance personnel can easily see how it is performing and what it is doing. For remote interfaces, the controller can communicate with your BMS via BACnet or Modbus and using MSTP or Ethernet. It can also operate independently with full automatic control.

The fluid can be a variety of ethylene or propylene glycol mixtures and, for warmer climates, water (don’t forget the corrosion inhibitor!). As part of our pre-engineered approach, selection is easy. Just provide our Applications Engineers with similar information that you would for a heat pipe: air flow rates, design summer and winter conditions, unit geometries, and desired supply condition. The one other thing we need to know is distance between air streams.

This system compliments the passive HRM-V, spanning longer distances (>200 ft), integrated controls, and the ability to recover in both seasons regardless of air flow position. However, if you are not sure which solution is better for you, we can easily provide selections for each, so you can compare side-by-side.

Please click the link below to view third party test:

⇒Intertek Performance Evaluation of Heat Pipe Technology’s SMART Water-Glycol Pump System

RECENT PROJECTS

This Product is Ideal for:

Hospitals

Laboratories

Processes

Let Our Zero Cross-Contamination Energy Recovery Solutions Help Your Bottom Line.