HPT’s Fluid Cooler line is ideal for process cooling, economizer applications (free cooling) and any requirement for closed-loop cooling systems utilizing water or brine. Example applications include data center cooling, and factory fluid cooling. The remote condenser line is ideal for heat rejection in supermarkets, process applications, chillers, pool dehumidification, and a myriad of other systems.

Both lines are designed with a high-capacity density (BTU/h per sqft) V‑coil configuration. Using HPT’s selection software, the coils can be configured from hundreds of combinations to tune the performance to the application, varying face area, number of rows, fin shapes, and circuiting.

All units are UL-1995 compliant.

Modules

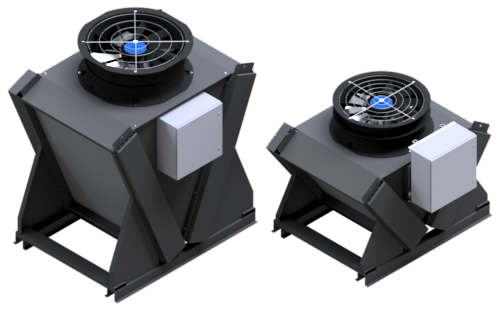

The modular design is based on two sizes:

- 33.75-inch face height coils, varying in length from one to five fans.

- 65-inch face height coils, varying in length from one to five fans.

In free standing applications, each fluid cooler has two coils, orientated in a ‘V’. Air is drawn from both sides of the unit. In applications with limited space, against a wall, for example, a one-coil option can draw air from one side only.

Dry or Adiabatic

The fluid cooler can be ordered in a dry or adiabatic configuration. The adiabatic configuration consists of a water distribution system designed to precool the ambient air prior to the air being pulled over the coils. With industry low water consumption, HPT’s adiabatic configuration achieves optimized saturation efficiencies necessary to meet the fluid leaving temperature setpoint. With drainable coils and other components in the product design, standing water is eliminated leading to health benefits over traditional systems. The adiabatic system is designed to operate only when needed thus minimizing energy costs year-round.

Controls

Controls maintain optimal performance, maintaining a fluid leaving temperature or a refrigerant sub-cooling temperature. A BACnet or MSTP compatible interface is standard, allowing the building’s automation system to view and control variables, like fluid/refrigerant set point.

Fan Options

- AC fans with starters – fans are controlled on/off

- AC fans with VFDs – fan speed is controlled

- EC fans – fan speed is controlled

In all cases, fans are controlled to maintain the minimum airflow required to reach fluid/refrigerant setpoint, so the system is operating with maximum efficiency.

Other Options

Standard materials comprise galvanized steel sheet metal, copper tubes and aluminum fins, whilst an array of upgrades can be applied to protect against environmental factors. Stainless steel casings, and dip coated coils are normal upgrades.

For help selecting the best solution on your project, please contact sales@heatpipe.com

This Product is Ideal for:

![]()

processes

![]()

data centers

![]()

Manufacturing

![]()

Sports facilities

Let Our Zero Cross-Contamination Energy Recovery Solutions Help Your Bottom Line.